Zero Liquid Discharge (ZLD) is a wastewater treatment process which is developed to completely eliminate all liquid discharge from a system by purifying and recycling the wastewater. This process leaves zero discharge at the end of the treatment cycle.Zero Liquid discharge is an advanced wastewater treatment that includes processes such as reverse osmosis, ultrafiltration, crystallization/evaporation, and fractional electro deionization.

The industries such as oil and gas, chemical, petrochemicals, mining, and other industries generate large volumes of wastewater that needs to be managed. These wastewaters are removed through a plant out to a water body, or a nearby pond or in some cases in the deep well. There is an increase in the environmental concerns regarding such disposal practices which have led to the development of Zero Liquid Discharge (ZLD).Companies may explore ZLD due to ever-tightening wastewater disposal regulations, company regulated green initiatives and concern over quality and quantity of water supply.

Zeal Solutions has an unmatched depth of experience in Zero Liquid Discharge (ZLD), including more than hundreds of installations having stand-alone evaporative/thermal processes, hybrid systems, or membrane processes.

Freshwater is an increasingly valuable resource which is threatened by the disposal of wastewater from industries unless the water is treated. Many industrial processes require water which reduces the freshwater availability for the environment or other processes or either it contaminates the local waterbody by releasing the wastewater making unfit for consumption.

Another reason to consider Zero Liquid Discharge is the ability to recover resources that are present in wastewater. Many organizations use ZLD for their waste to sell the solid produced or reuse again in the industrial process. For example, gypsum is recovered from flue gas desalinization(FGD) wastewater and mine water which can be sold for drywall manufacturing.

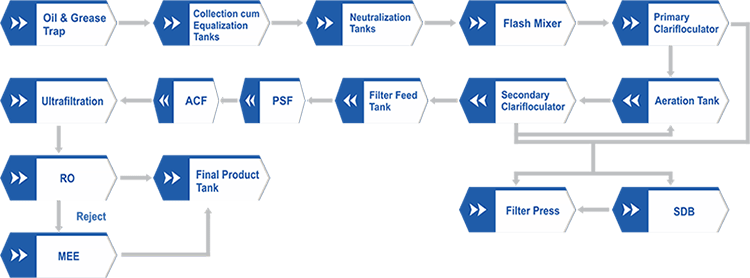

The initial step to achieve ZLD is to limit the amount of wastewater which needs to be treated. The selection of the equipment needed will depend on the volume of dissolved material in waste, the system’s required flow rate and the specific contaminants present in it.The conventional approach to ZLD is using of filtration technology, funnel the reject waters to an evaporator and send the evaporator concentrate to a spray dryer. ZLD treatment process includes steps such as pretreatment and conditioning, phase-one concentration, evaporation/crystallization, solid waste treatment/ recycled water distribution

Equipment for this purpose is quite expensive and large which confines the cost-effectiveness to those having very large waste streams.

Zeal Solutions provides you with thermal and non-thermal ZLD solutions to manage wastewaters. We provide equipment such as evaporators, brine concentrators and crystallizers which can help recover nearly 90% of the plant's wastewater and reducing the remaining to product or solid. Zeal's Sievers and Analysers helps in controlling the water quality to be recycled in semiconductor operations.

We, Zeal Solutions, offer a comprehensive set of chemical and equipment solutions and services available, helping to manage and optimize the water resources and the process challenges across industries.

Our goal is to meet the increasing water demands and the population needs, overcome the scarcity challenges and comply with the environmental regulatory requirements.

We partner with our customers in order to reduce the costs and prepare for the evolving demands of the industry.

Let's talk to discover possiblities

Get in Touch

(The Water Treatment & Environmental Management Group)